CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

1. When choosing a bearing brand for industrial robots, you can consider the following factors:

1. Quality: Choosing a bearing brand with high quality and good performance can ensure the stability and accuracy of the robot. Some well-known bearing brands, such as NSK, SKF, FAG, etc., enjoy a good reputation in the market and can be used as a reference for selection.

2. Applicability: Different bearing brands and models are suitable for different application scenarios and needs. Choosing bearing brands and models that suit the specific needs of industrial robots can improve the adaptability and reliability of the robot.

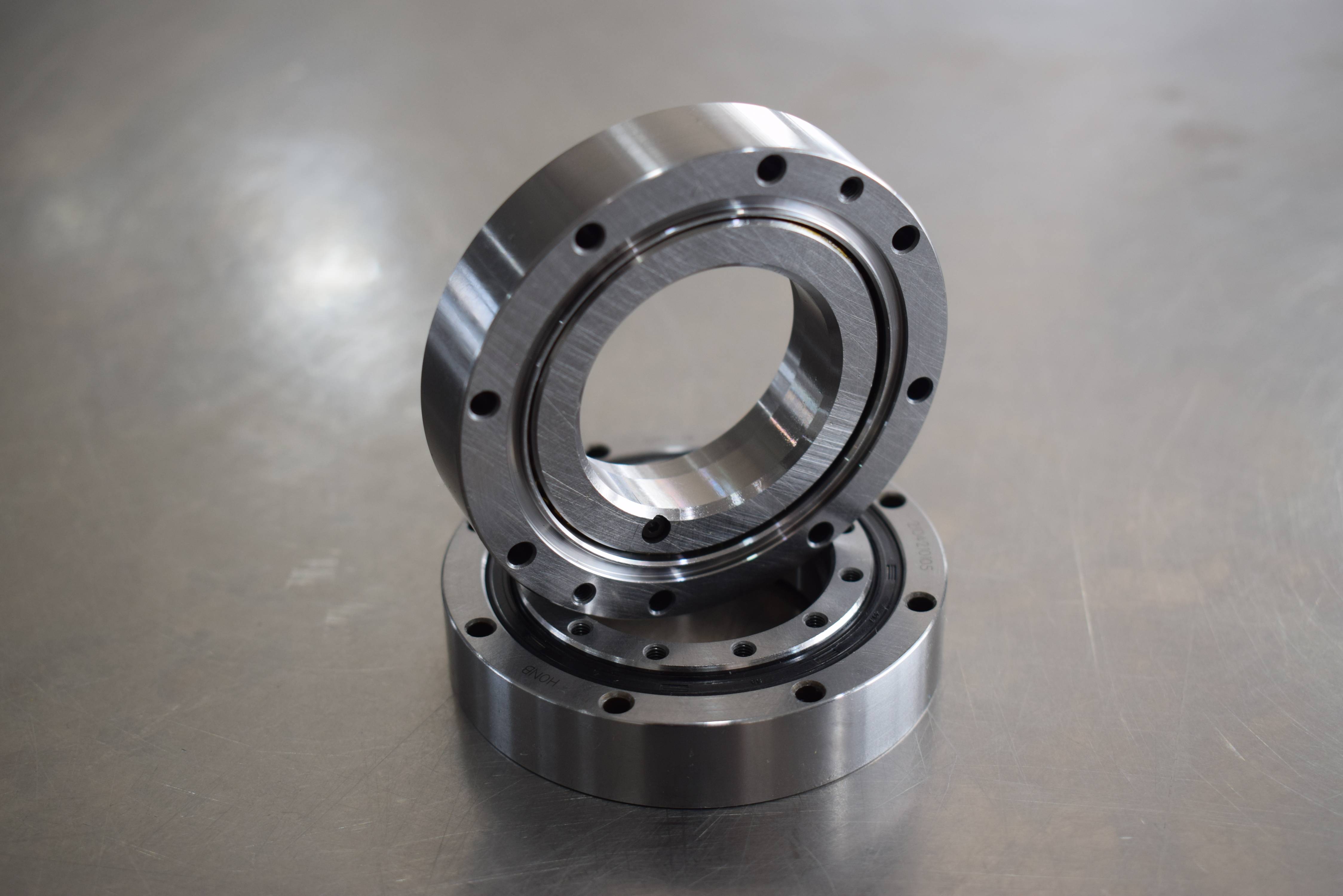

3. Bearing type: Select the appropriate bearing type according to the specific application and needs of the industrial robot. For example, for robots that need to withstand heavy loads and high rotational speeds, bearings with high load-bearing capacity and high-speed performance need to be selected.

4. Size range: Different brands of bearings have different size ranges. It is necessary to select the appropriate bearing size according to the design size requirements of the industrial robot.

5. Performance requirements: Industrial robots have high performance requirements for bearings, including rotation accuracy, rigidity, wear resistance, fatigue resistance, etc. Bearing brands with excellent performance need to be selected based on these requirements.

6. Reliability: Industrial robots require long-term, high-intensity work, so they need to choose bearing brands with high reliability. Choosing a bearing brand that has undergone strict quality testing and long-term verification can ensure the stability and reliability of the robot.

7. Cost: The cost of bearings is also one of the factors that need to be considered when selecting. On the premise of ensuring quality and performance, choosing a reasonably priced bearing brand can reduce the cost of the entire robot machine.

8. Supply cycle and after-sales service: Choosing a bearing brand with stable supply capabilities and perfect after-sales service can ensure the smooth progress of robot production and maintenance.

Choosing a bearing brand suitable for industrial robots requires comprehensive consideration of multiple factors, including bearing type, size range, performance requirements, cost, supply cycle and after-sales service, reliability, etc. When making specific choices, you can evaluate and select the most suitable bearing brand based on actual needs and budget.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.