CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

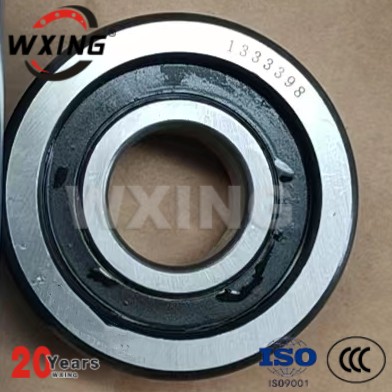

TYPE:Forklift bearings

ITEM NUMBER:1333398

Size 35x92x31

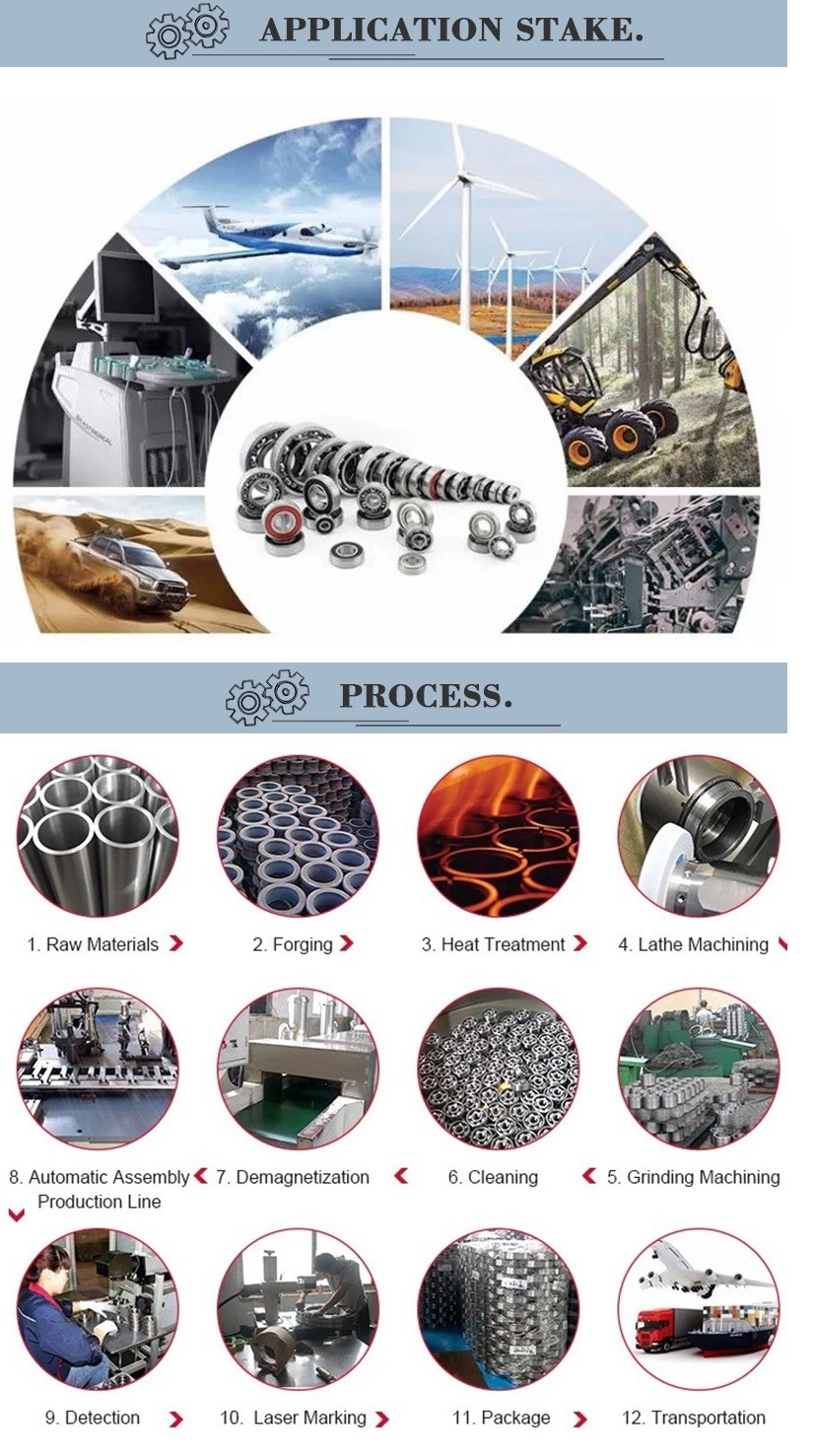

Forklift Mast Roller Bearing is used in a very important metal parts, forklift truck work in the hair bearing play an irreplaceable role.

Industrial handling vehicles are widely used in ports, railway stations, airports, freight yard, workshop, warehouses, distribution centers and distribution centers, and access to the cabin, carriages and containers for loading and unloading pallets, handling operations.

Fork Lift Bearings are a blend of simple design and assembly. A pillow bearing has deep groove ball bearing, which is sealed on both sides and a spherical diameter on the outside with housing. The housing is either a casting or a sheet metal stamping. The Fork Lift Bearings are resistant to temperatures, dimensionally accurate and have high functionality.

Forklift Mast Roller Bearing lubrication

Forklift Mast Roller Bearing lubrication, first open the cover and watch to check the release bearing wear, if they are recognized bearing no damage or wear is not overrun, remove the clutch pedal adjustment mandrel release bearing and its seat back to the last position,butter filling to the bearing hole with a needle nose grease gun until the bearing oil spill, then slightly turn the bearing oiling again, repeat the above work, a little butter until around the bearing has an overflow, and then the bearing rotation observed oilIf you feel the the bearing rotation resistance,that bearings have been filled with butter. Then clear separation of a small amount of butter, and re-adjust the separation bearing position throughout the bearing seat overflow

Forklift Mast Roller Bearing Precautions

1, To keep the forklift bearing its surroundings clean

Even if the the invisible smile dust into the forklift bearings will increase bearing wear, vibration and noise.

2, Using the installation to be carefully

Not allow powerful punch forklift bearing, does not allow a direct hit with a hammer, and not allowed to pass through the rolling pressure.

3, The use of appropriate, accurate installation tools

To make use of a special tool, and tried to avoid using something like cloth and short fiber.

4,To prevent the corrosion of forklift bearings

Handle forklift bearing directly to wash hands sweat, and coating quality mineral oil and then operate, with particular attention to anti-rust during the rainy season and summer.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.