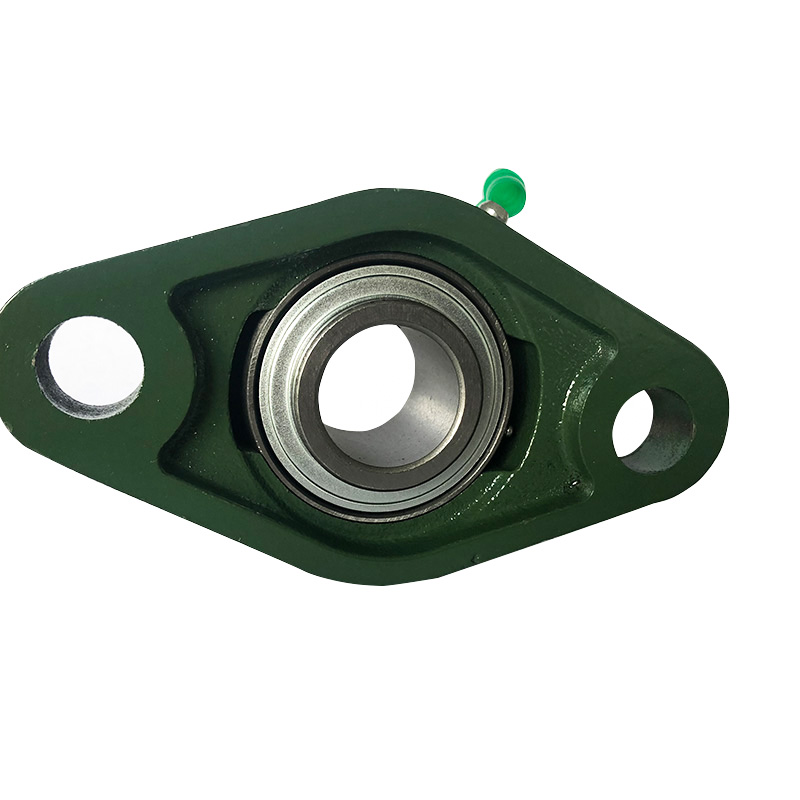

Spherical bearing with seat

Mounting Spherical Plain Bearings

To facilitate mounting, the ends of pins or shafts and the edges of housing bores for spherical plain bearings should have a lead chamfer of 10° to 20°. The bearings can be more easily pressed into position and there is little risk of damage to the mating surfaces being caused by skewing of the bearing.

When mounting spherical plain bearings with a fractured or two-part outer ring, it is essential that the joint should be positioned at 90? to the main load direction; otherwise the service life will be shortened, particularly under heavy loads. Also, the bearing’s lubrication holes will be placed in the load zone, allowing lubricant distribution where it is needed most.

Bearing rings should NEVER be hammered into place. Only apply mounting forces onto the ring that is being mounted (i.e. force on outer ring if being pressed into a housing, force on inner ring if pressed onto a shaft). NEVER apply mounting forces though the bearing’s sliding surfaces, this will damage the bearing and will severely decrease its service life. In the event that the bearing has a press fit on both the inner and outer rings, a special tool should be made to allow pressing of both components simultaneously.

Other ways of mounting with the facilitation of heat or refrigeration, or with the use of adhesives may be possible also, please contact AST Engineering for further assistance.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.