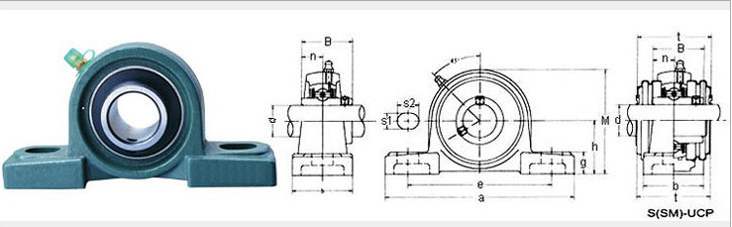

Spherical bearing with seat

Spherical bearing seat bearing introduction

The spherical bearing seat bearing is actually a variation of deep groove ball bearing, which is characterized by that its outer ring outer diameter surface is a spherical surface, which can be matched into the corresponding concave spherical surface of the bearing seat to play the role of centering.

Although spherical bearing seat bearing basic performance with deep groove ball bearings should be similar, but because of the bearing are mostly applied in mechanical rough, installation location is not accurate, the axis of the shaft with a hole to neutral, or under the condition of large axial length and deflection etc, and the spherical bearing seat bearing itself precision is not high, some structure is rough, so the performance of the actual performance comparison on the same specifications of the deep groove ball bearings to play quite a discount.For example, the outer ball bearing with the top wire is applied to the through shaft with large stiffness deflection.

The spherical bearing seat bearing is mainly used to bear combined radial and axial loads, which are mainly radial loads. Generally, it is not suitable to bear axial loads separately.

his kind spherical bearing seat bearing can be installed with inner ring (with full set of rollers and retainers) and outer ring respectively.The bearing does not allow the shaft to be tilted relative to the housing, and additional axial forces will be generated under radial load assignment.The size of axial clearance of the spherical bearing seat bearing has a great relationship with whether the bearing can work normally.Bearing is easy to damage when axial clearance is large.Therefore, special attention should be paid to adjust the axial clearance of the bearing during installation and operation. If necessary, it can be preloaded and installed to increase the rigidity of the bearing.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.