High corrosion-resistant bearings are applicable in corrosive environments such as water, weak acid and alkali, and strong acid and reactive gas. High corrosion-resistant bearings include stainless steel bearings, Molded-Oil? bearings, and corrosion-resistant coated bearings (Nickel coating) for water environments; ceramic bearings and ESA bearings for weak acid and alkali environments; and ceramic bearings and the Aqua-Bearing™ for strong acid and reactive gas environments.

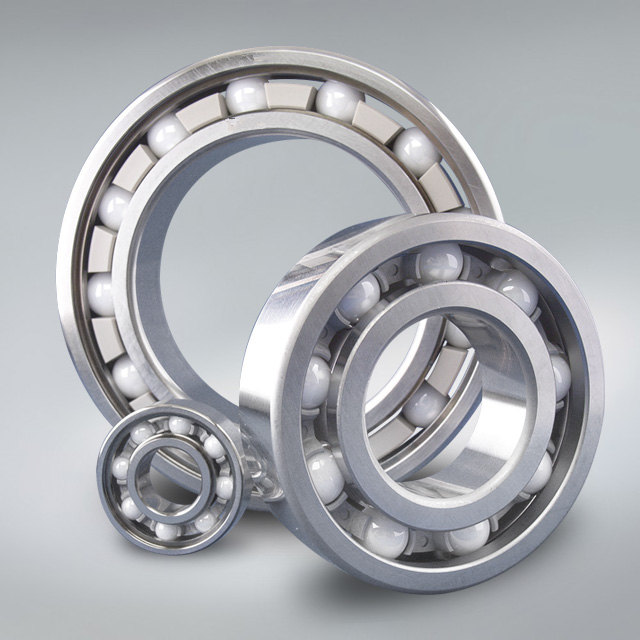

Stainless Steel Bearings

Stainless steel bearings, the standard products of the WXING SPACEA Series for special environments, are suitable for high-humidity environments.

Molded-Oil™ Bearings

Molded-oil bearings, made of stainless steel, are lubricated with WXING's original oil-impregnated material, Molded-oil™, and are suitable for corrosive and dust-contaminated environments in normal atmosphere.

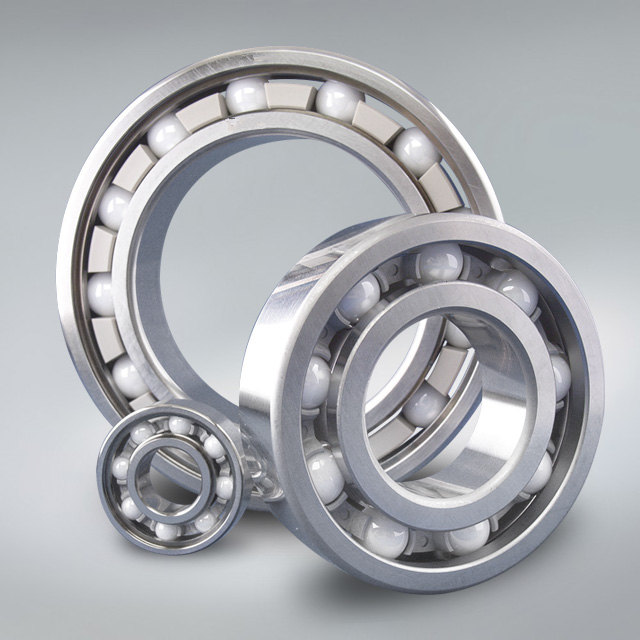

Hybrid Bearings

Hybrid bearings, combining ceramic balls and fluororesin self-lubricating cages, are suitable for corrosive environments from normal atmosphere up to vacuum.

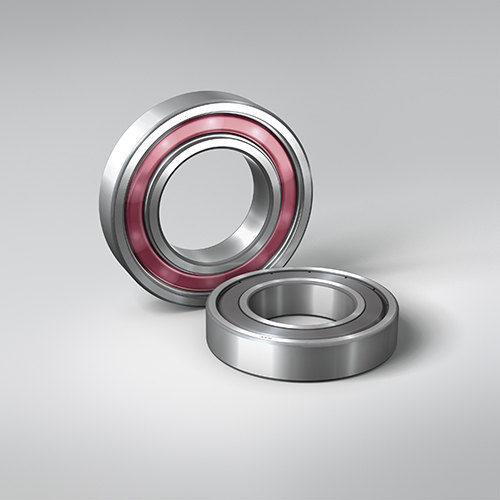

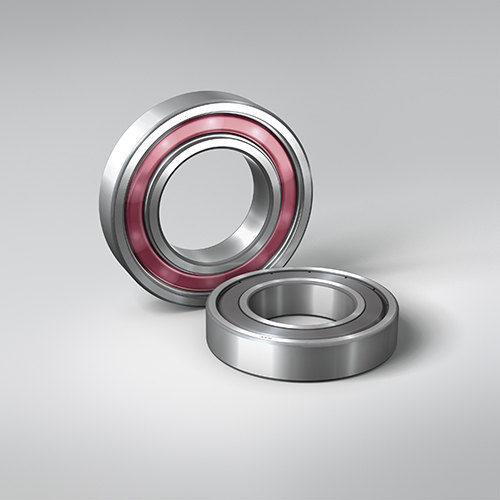

Corrosion-Resistant Coated Bearings

Corrosion-resistant coated bearings (Nickel coating) are coated with a nickel coating on the outer and inner rings to enhance corrosion resistance and durability, and are suitable for corrosive environments such as normal atmosphere or high temperature.

High corrosion-Resistant, high hardness stainless steel ESZ Bearings

ESZ Bearings have corrosion-resistant, and are superior to martensitic stainless steel.

The bearings are having corrosion resistance equal to precipitation hardening type stainless steel and the hardness is improved more than 30%.

The bearings are suitable for corrosive environment operating under atmospheric conditions.

High Corrosion-Resistant, Non-Magnetic Stainless Steel ESA Bearings

ESA bearings, combining austenite stainless steel and hardened surface layers, possess high hardness, corrosion resistance and non-magnetic properties, and are suitable for corrosive environments and non-magnetic requirement in normal atmosphere and vacuum.

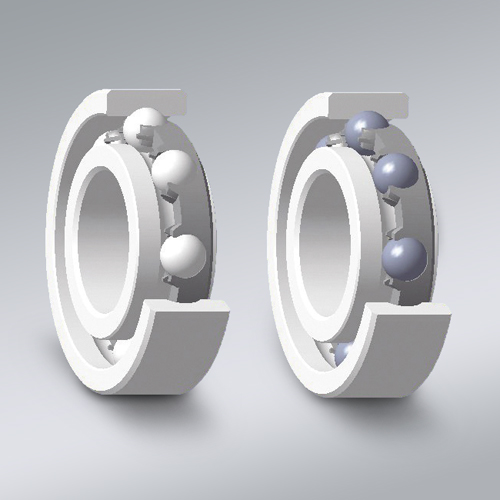

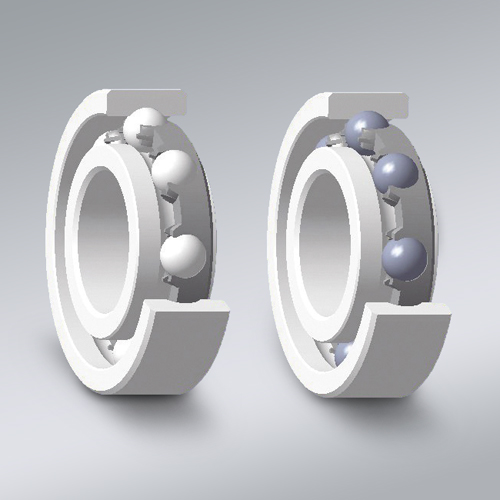

All-Ceramic Bearings (Oxide-based ceramics)

With ceramic outer/inner rings and balls, all-ceramic bearings have self-lubricating fluororesin cages and are suitable for corrosive environments and non-magnetic requirement from normal atmosphere up to vacuum.

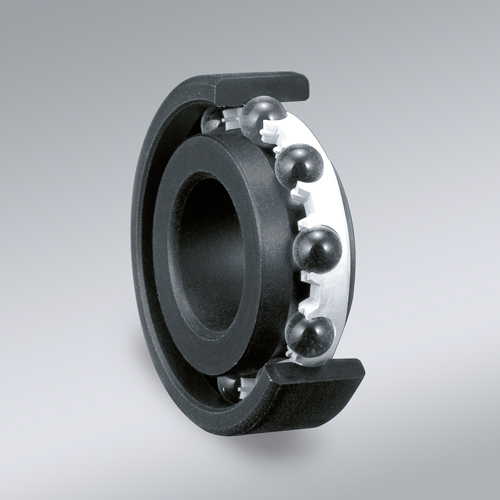

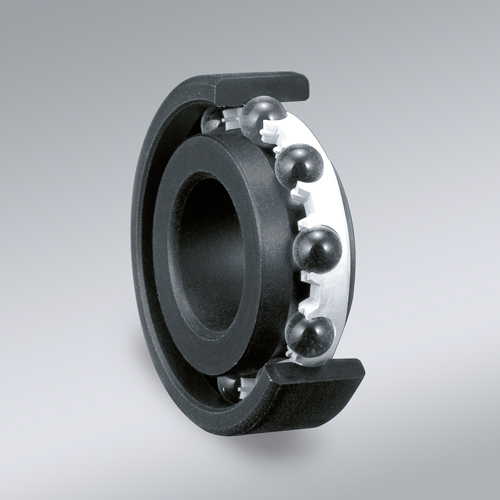

Aqua-Bearings™ High Corrosion-Resistant Resin Bearings

Aqua-bearing features a special fluororesin for outer/inner rings and cages equipped to meet a broad range of applications in water, alkali and strong acid environments. Aqua-bearing is suitable for corrosive environments exclusively in normal atmosphere.