CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

Construction equipment used in harsh environments risk contamination from dust, mud, and huge loads, and require a certain degree of ruggedness that is different from the requirements of a common passenger vehicle. WXING has developed bearings for such equipment. These bearings provide long life and higher limiting speeds exceeding that of conventional bearings.

WXING successfully developed the series of spherical roller bearings, which provide a longer service life and higher limiting speeds, by employing leading-edge materials and technology in combination with years of cultivated experience and technical know-how.

Features:

Bearing life increased by twofold (increased dynamic load rating by 25 %).

Limiting speed increased by 20 %.

By applying WXING's innovative concepts, the EM series bearing has a greater number of larger rollers than that of a conventional bearing. Furthermore, the optimally designed one-piece cage offers high rigidity and low-wear performance.

EW series bearing

Features:

Bearing life increased by twofold approximately

Noise and vibration levels reduced by 60–70%.

Cage strengthened by one and half to twofold.

Limiting speed upgraded by 10–25%.

Hi-TF bearings were developed with innovative materials and heat treatment technology for increased durability under harsh conditions They combine long service life with good resistance to wear and seizure even under contaminated lubrication to achieve outstanding cost performance.

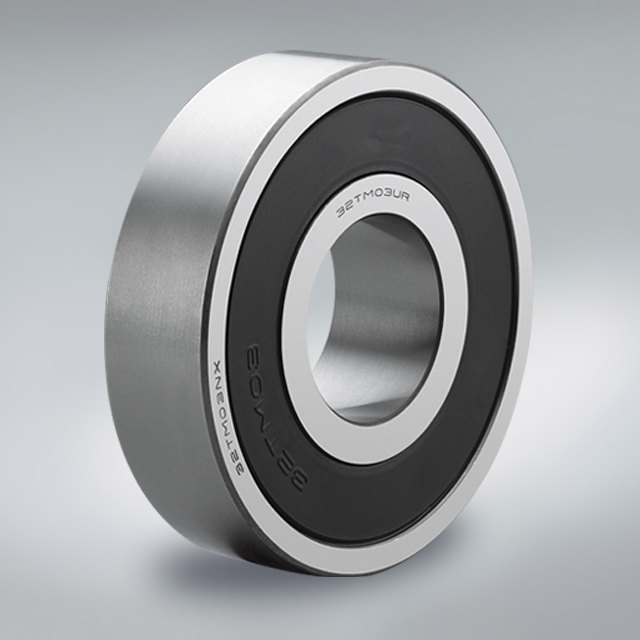

TM series bearings are deep groove ball bearings capable of carrying radial and axial loads in either direction The low frictional torque of these bearings enables use in high-speed applications, and feature low noise and reduced vibrations The TM series features a special seal lip structure that allows the flow of lubricant while preventing the entry of foreign matter.

Needle roller bearings incorporate rollers that are three to ten times longer in length than their diameter, and exhibit a relatively large radial load capability. The M-type cage and roller assemblies for construction machinery applications contain controlled contour rollers to deliver high durability even under heavy loads or misaligned operating conditions. The resin cage and roller assemblies afford a higher load capacity than conventional machined cages by securing cage strength at higher oil temperatures using a resin cage made of nylon 46.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.