CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

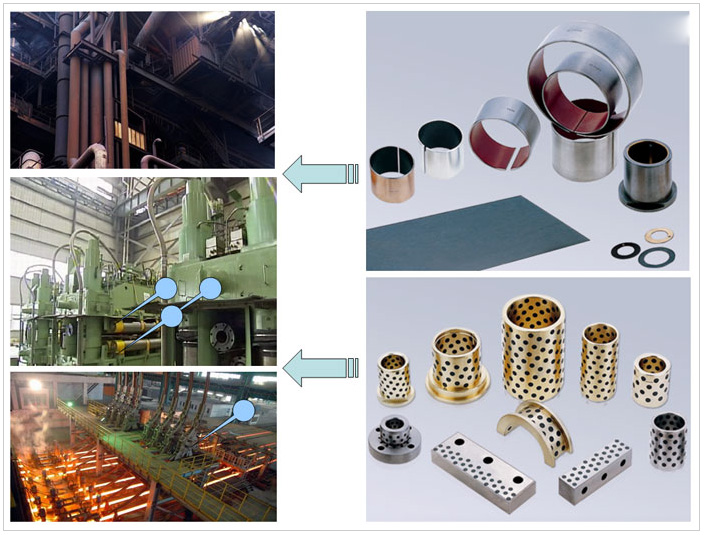

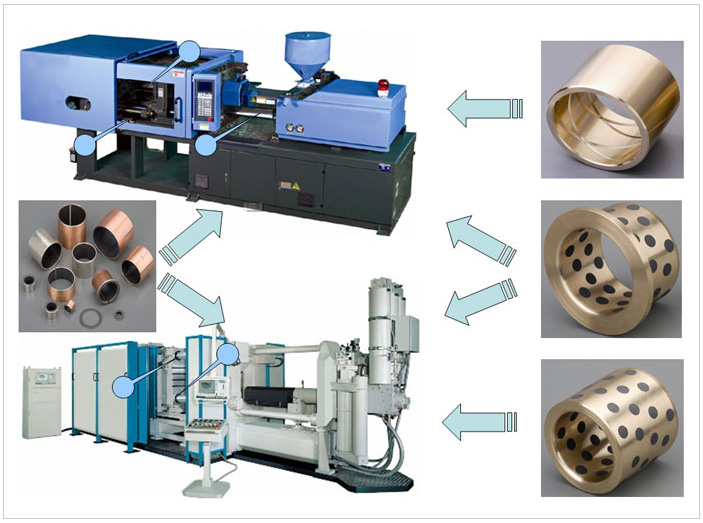

Use of oil-free bearings

Oil-free bearings use water-soluble cutting fluid, and users must make more efforts in machine tool maintenance and management to control the occurrence of erosion, and even basically eliminate erosion. In order to prevent water from eroding the metal surface, the machine tool should always be fully lubricated with oil, and grease should be applied to the important parts of the machine tool.

Oil-free bearings can have a long life under accurate use. If premature damage occurs, it is likely to be caused by wrong selection, improper use or poor lubrication.

Therefore, when installing the bearing, we need to record the type of machine, the installation location, the premise of use and the nearby coordination. Summarize the type of bearing damage and the use environment when the problem occurs, so as to avoid similar situations from happening again.

Correctly control the concentration of cutting fluid. When the machine tool is shut down, flush the surface of the machine tool with cutting fluid, and open the machine guard to disperse the humid air in the working area of the machine tool. In order to prevent the occurrence of electrical corrosion, a layer of waterproof grease should be applied to the metal surface. In addition, the machine tool should be grounded strictly. It is not enough to ground the electrical cabinet. In order to avoid the breeding and reproduction of bacteria, the cutting fluid should be cleaned or replaced on time, the chips should be removed in time, and soft water (pure water with low mineral content) should be used. ) to dilute the cutting concentrate.

In addition to the excellent quality, oil-free bearings are also very precise parts. They are high-performance bearings. If they are used improperly during use, they will not only fail to achieve the expected functional effects, but also easily damage the bearings. In terms of lubrication, everyone is sure All have noticed.

1. Be very careful when using and installing, do not allow strong stamping, do not use vertical tap bearings, and do not allow pressure to be transmitted through the moving body.

2. Use appropriate and correct installation tools, try to use special tools, and try to avoid the use of cloth and short fibers.

3. Try to keep the bearing and its surrounding environment clean. Even if the invisible dust enters the bearing, it will increase the wear, vibration and noise of the bearing.

4. Prevent the rust of the bearing. When taking the bearing directly by hand, fully wash off the liquid on the hand, and apply high-quality mineral oil before operating, especially in the rainy season and summer, pay attention to rust prevention. Under certain special operating conditions, oil-free bearings can achieve longer life than traditional calculations, especially under light loads. The premise of these special operations is that when the moving surfaces (tracks and moving parts) are effectively separated by a lubricating oil film and limit possible surface damage caused by contamination. In fact, under ideal conditions, so-called permanent bearing life is possible

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.