CONTACT US

Zhejiang waxing electromechanical co.LTD.,Factory located in Shandong,Headquarters located in Zhejiang,China.

Angular contact ball bearings can bear radial and axial loads at the same time, and can work at higher speeds.

Mainly used in metallurgical equipment, mining machinery, construction machinery, paper machinery, wind turbines, semiconductors, machine tools, gear devices, motors (motors), pumps and compressors, injection molding machines, motorcycles and other fields.

Today, let's learn about the classification and characteristics of angular contact ball bearings.

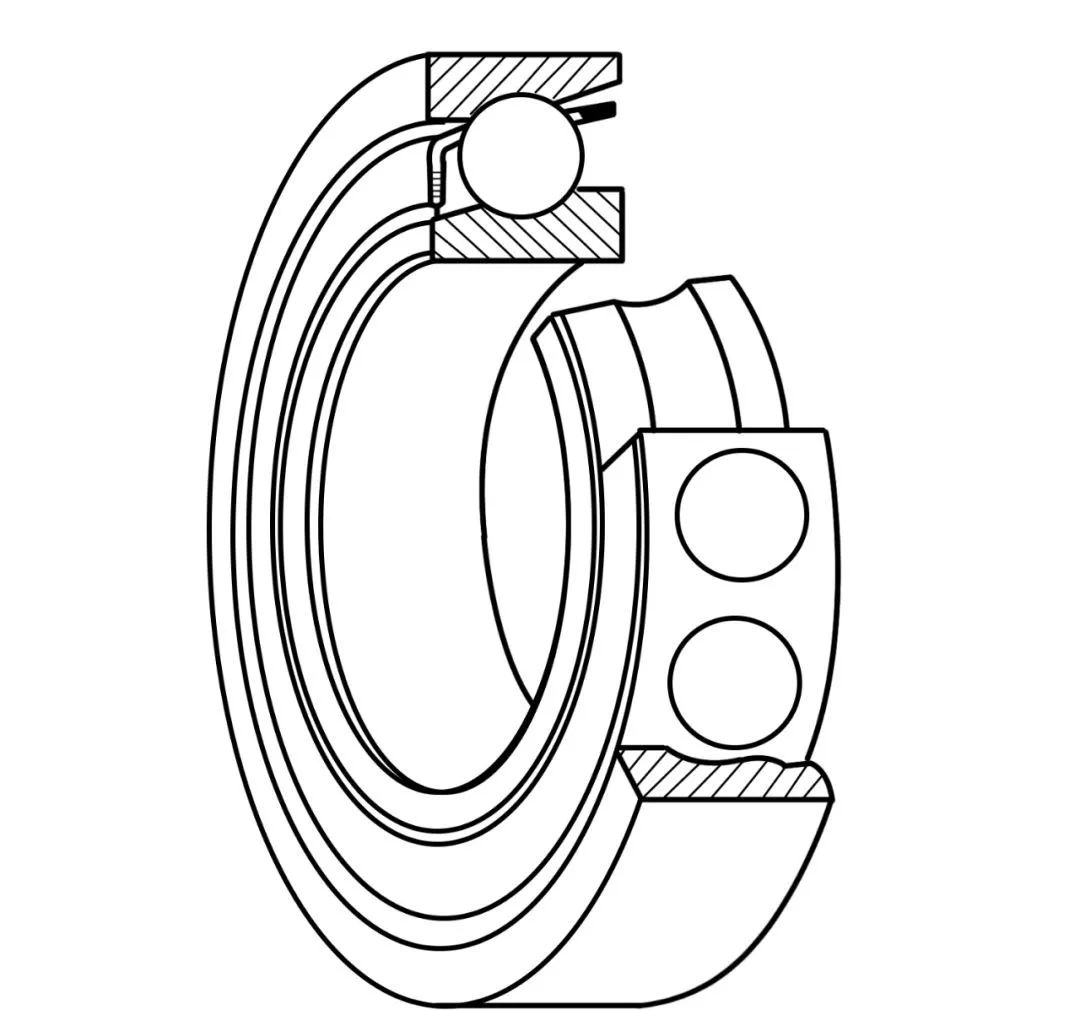

No.1 Single row angular contact ball bearing

This bearing has a contact angle, so it is suitable for bearing axial loads in one direction, or combined loads.

Structurally, the axial component force is generated after bearing radial load, so two bearings are used oppositely, or two or more bearings are used in pairs.

Single row angular contact ball bearings can use the preload method to improve rigidity, so they are suitable for machine tool spindles with high rotational accuracy.

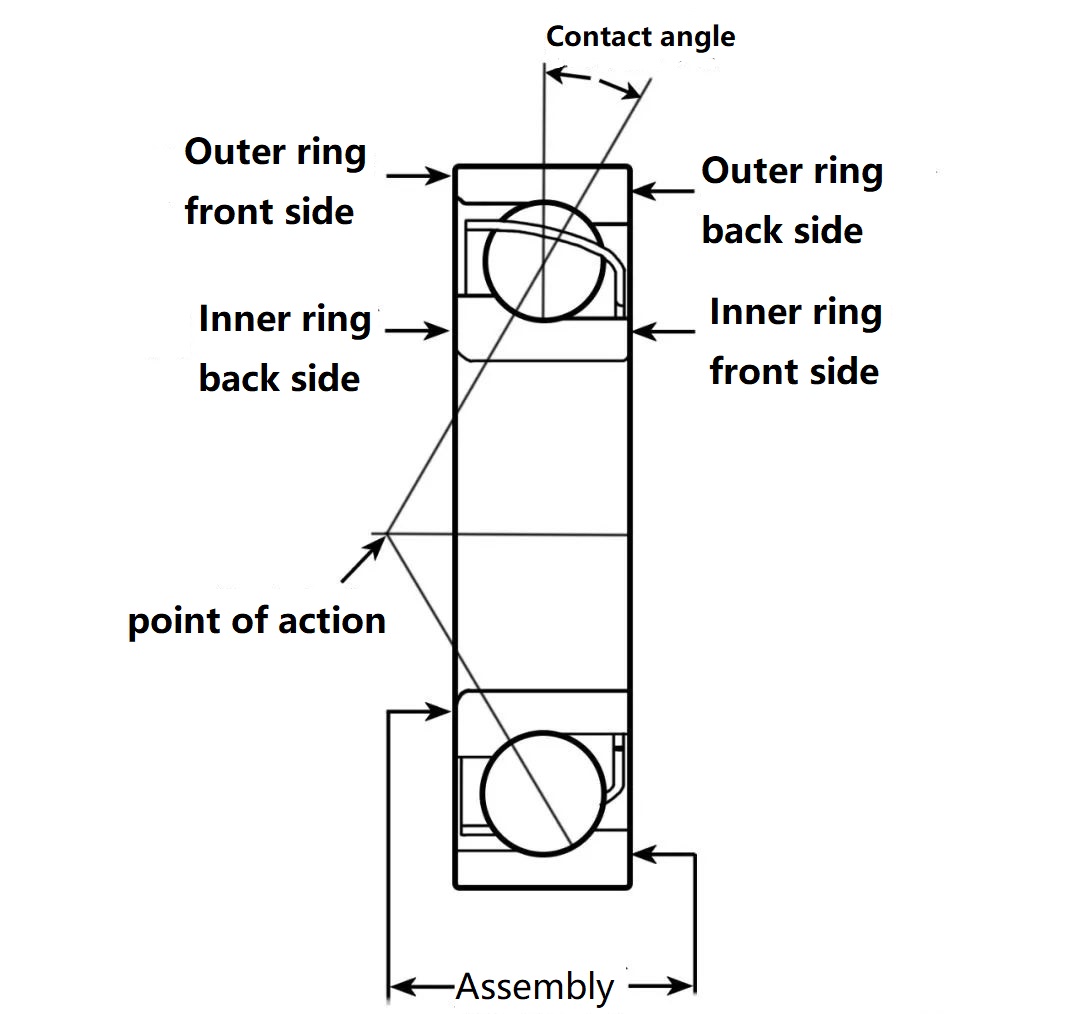

No.2 Paired double angular contact ball bearings

Combining two sets of radial bearings into pairs becomes a paired double bearing. Usually paired duplex bearings are composed of the same angular contact ball bearings.

Paired double angular contact ball bearings are divided into three categories:

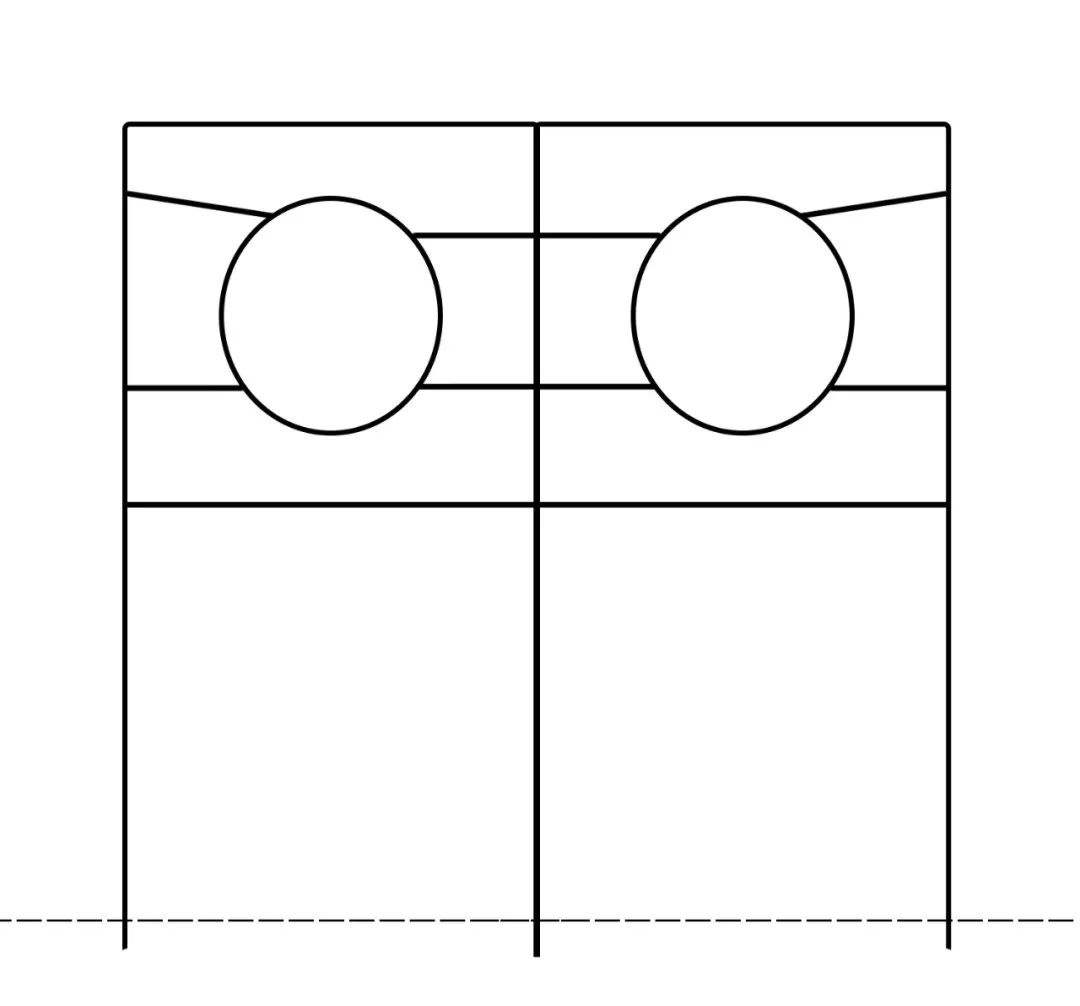

1. Back-to-back configuration

Can bear radial load and axial load in two directions.

The distance between the action points is large, so it is suitable for applications with large moment loads.

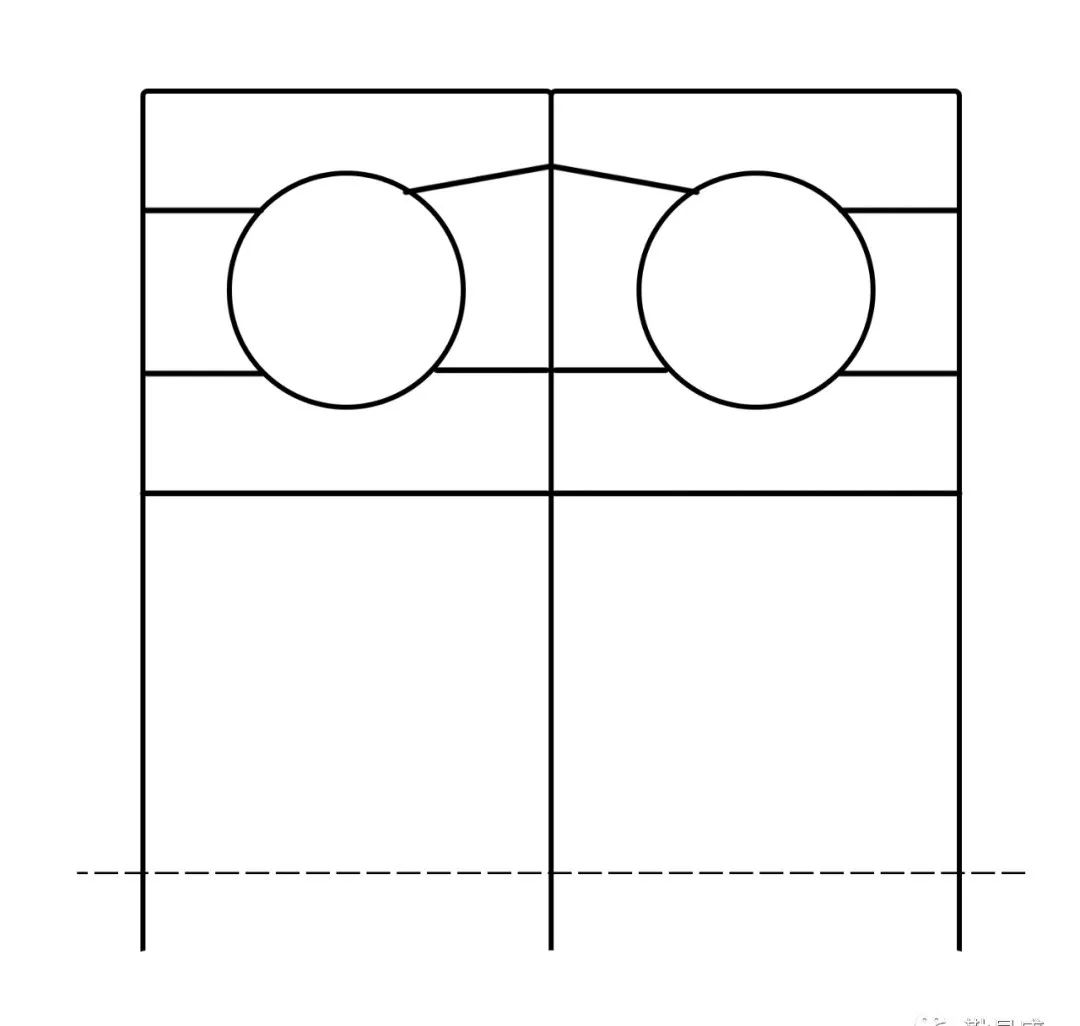

2. Face to face configuration

Can bear radial load and axial load in two directions.

Compared with the back-to-back duplex, the distance between the action points is small, so the moment load capacity is poor.

3. Tandem configuration

Can withstand radial loads and axial loads in one direction. The axial load is supported by two bearings, so it is used for occasions where the load in one direction is large.

Solutions for paired bearings

a. High-end imported bearings adopt universal matching bearings

As shown in the figure below, the 7310BEGAP bearing has a height tolerance of only ±0.004mm

universal matching images

Thereby, universal pairing is realized, and the advantage is that it is easy to install. However, the disadvantages are also obvious. Due to the high processing requirements, the price is relatively high, which is suitable for high-end occasions.

b. The most economical solution: use paired bearings-----pairing images

The corresponding suffixes are DB, DF, and DT, respectively. This is a relatively economical solution.

Copyright © 2025 Zhejiang waxing electromechanical co.LTD. | All Rights Reserved Design

Hello, please leave your name email or WhatsApp here before chat online so that we won't miss your message and contact you smoothly.